Sorry, forgot to address one of your comments...

The Trainpack has a speed control lever that has no effect on the track voltage, So it must change the current.

Your Trainpack is an

unregulated power supply. It is a passive device. The voltage

and current change (inversely) depending upon load and rheostat position. The article is about

regulated power supplies only. The article applies to wall warts.

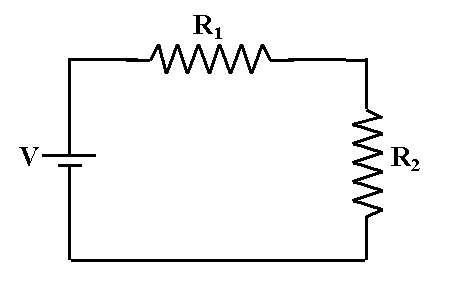

Electrically, this is your Trainpack and a locomotive:

With R

1 being the speed lever and R

2 the locomotive. R

1 changes with lever position, R

2 changes with loco speed and load. Ohm's law states the circuit current is determined by R1 + R2. It also states voltage drop across R

2 = V - R

1 drop. Since both R

1 and R

2 continually change as you operate the train there will also be changes in voltage across and current through R

2 - your locomotive.

A regulated power supply will either: A) maintain a constant voltage regardless of R

2 value; or B) limit the total circuit current to the value produced by R

2. Voltage regulation is important to RP. Current regulation is not needed in the power supply as the LM already does this (loco stall setting on your HC). It is a misnomer of sorts to say current regulation. It is more accurate to say current limiting. Any device will only pass as much current as its internal R determines. Current regulators are for use with devices that have low R but not the ability to handle the current (heat) that such a low R would produce. LEDs are prime examples. Model train motors are bulky sturdy devices with the ability to dissipate a lot of heat. They only have a problem dissipating heat from excessive current when the R falls to very low. And even then it takes time for the heat to build up. The HC stall setting, AKA power supply current regulation/limiting, keeps the current below the critical point for the loco motor during low R instances (stalled or extreme loading).

Does that help?